The Ultimate Guide to Custom XLPE Foam Solutions & Packaging in India

Custom XLPE foam is fast becoming the material of choice for businesses across India that need durable, lightweight, and versatile packaging and fabrication solutions. At Foamkart, with over 20 years of expertise in foam fabrication, we help industries from automotive to electronics and healthcare find the perfect XLPE foam solutions tailored to their needs. Whether you need precision-cut inserts for tools, shock-absorbent packaging for medical equipment, or durable protective foam for logistics, Foamkart delivers India’s most reliable custom foam products.

What Is XLPE Foam and Why It Matters

XLPE (Cross-Linked Polyethylene) foam is a closed-cell foam material known for its unique properties:

- Excellent shock absorption and vibration resistance

- Lightweight yet structurally strong

- Water, chemical, and weather resistant

- Non-toxic, recyclable, and eco-friendly options available

- Can be die-cut, CNC routed, or custom molded for precise applications

These qualities make XLPE foam the preferred choice for packaging, insulation, sports equipment, and industrial protection. Unlike open-cell foams, XLPE foam provides enhanced durability and longer product life, reducing costs for businesses.

Learn more about Foamkart’s heritage and expertise on our About Us page.

Applications of Custom XLPE Foam in India

At Foamkart, we specialize in custom XLPE foam solutions for a wide variety of industries. Our products are designed to meet strict performance and safety requirements while offering cost-effective benefits.

Automotive Industry

- XLPE foam gaskets, seals, and protective inserts

- Sound insulation and vibration dampening

- Durable protective packaging for automotive parts

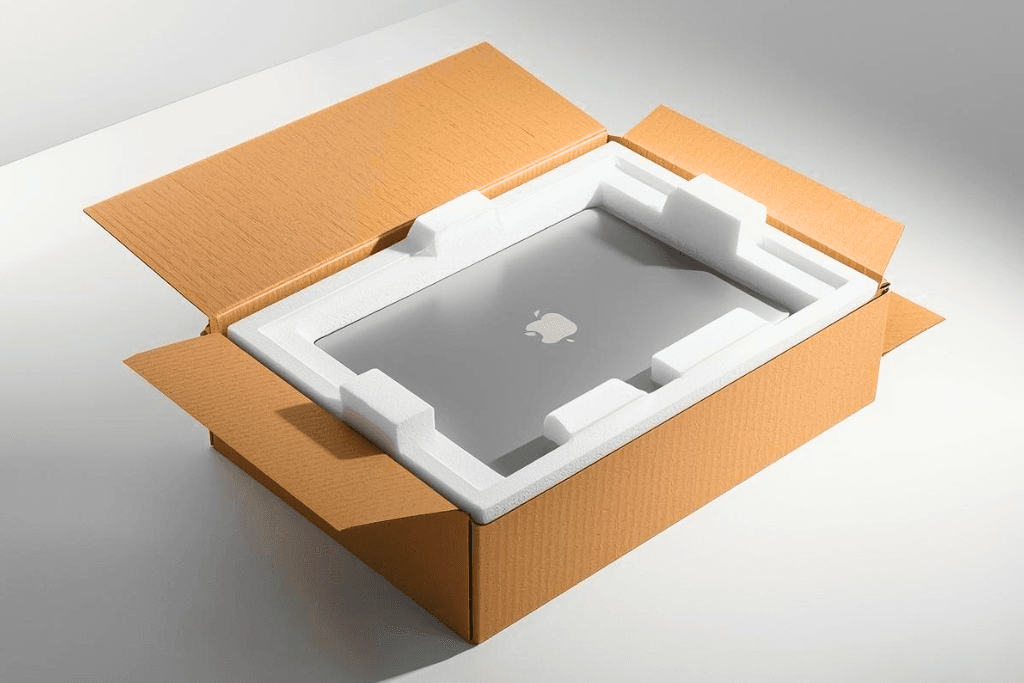

Electronics and Electricals

- Anti-static XLPE foam packaging for circuit boards and sensitive components

- Foam trays for mobile devices, laptops, and accessories

- Cable and wire insulation solutions

Healthcare and Medical Devices

- Sterile packaging for diagnostic and surgical instruments

- Protective cushioning for fragile medical equipment

- Lightweight foams for rehabilitation and support products

Sports and Lifestyle Products

- Shock-absorbing mats, padding, and protective gear

- Custom inserts for premium sports equipment

- Weather-resistant foam for outdoor gear

Industrial and Export Packaging

- Custom XLPE foam inserts for toolboxes, equipment cases, and transit packaging

- Returnable packaging solutions for logistics companies

- Foam pallets and trays for high-value shipments

XLPE Foam Packaging: The Smart Choice for Protection

When it comes to EVA and XLPE foam packaging in India, Foamkart leads the way with innovative, industry-focused solutions. Our XLPE foam packaging ensures:

- Shock resistance to prevent transit damage

- Moisture and chemical resistance for long-distance shipping

- Reusable and eco-friendly designs for sustainable businesses

- Customization with die-cut inserts, CNC routing, and foam layering

This makes Foamkart’s packaging ideal for fragile goods, export shipments, and premium branding needs. For more insights, explore our blog on choosing the right foam for packaging.

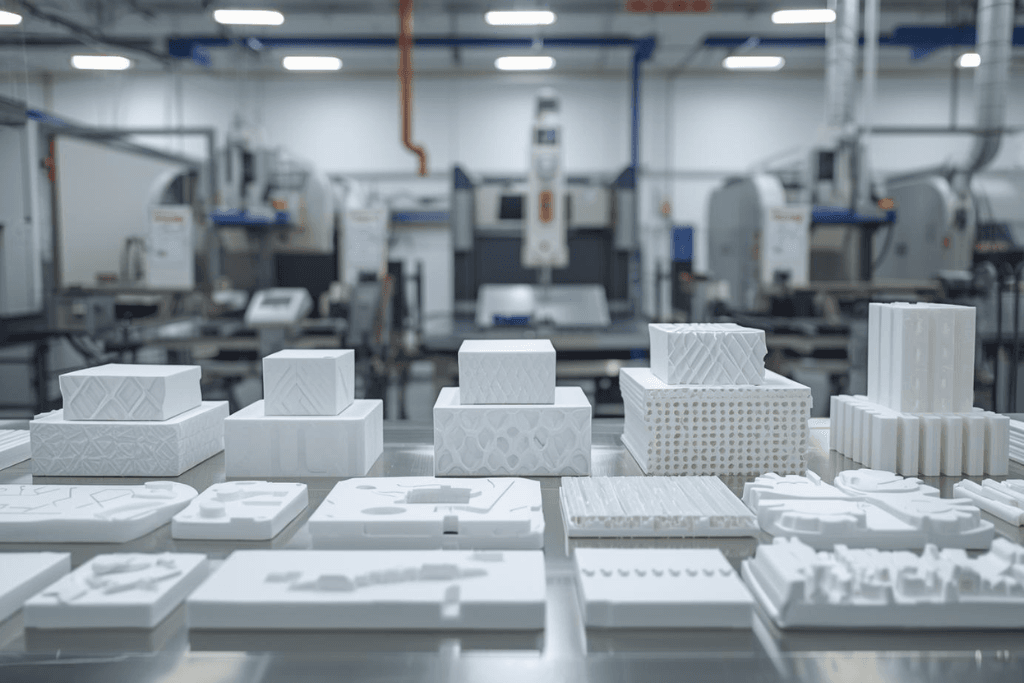

Foamkart’s Advanced Foam Fabrication Capabilities

With 20+ years in the market, Foamkart has developed world-class facilities and expertise to deliver precision and scalability. Our services include:

- Foam Splitting & Slicing – for sheets and slabs of desired thickness

- CNC Foam Milling / Routing – for precision designs and intricate inserts

- Foam Die Cutting – for high-volume, accurate shapes

- Custom Prototyping – so you can test before full production

Our team works closely with clients from concept to final delivery, ensuring your foam solution is both functional and cost-efficient. Read how we’re revolutionizing custom foam solutions in India.

Nationwide Reach and Location-Based Expertise

Foamkart proudly serves clients across India, delivering custom XLPE foam products to both large enterprises and startups. Our reach covers:

- Mumbai (Andheri, Navi Mumbai, Thane)

- Delhi NCR (Noida, Gurgaon, Rohini, Dwarka)

- Bangalore (Electronic City, Whitefield, Jayanagar)

- Hyderabad (Hitech City, Banjara Hills, Gachibowli)

- Chennai, Pune, Ahmedabad, Jaipur, Kolkata, Coimbatore

- Over 100 Tier-2 and Tier-3 cities like Indore, Lucknow, and Visakhapatnam

Wherever you are located, Foamkart ensures localized delivery with national scalability.

For details on our design-to-delivery process, explore the foam fabrication process blog.

Why Foamkart Is India’s Leading XLPE Foam Provider

- 20+ Years of Experience in foam fabrication

- 7000+ Clients across industries

- ISO-Certified Materials for quality assurance

- Custom Orders – from small-scale prototypes to large-volume production

- Cost-Effective Pricing with unmatched turnaround times

Ready to discuss your requirements? You can easily book an appointment with our experts today.

Frequently Asked Questions (FAQs)

What are the key benefits of using XLPE foam for packaging?

XLPE foam provides excellent cushioning, moisture resistance, and durability, making it ideal for packaging fragile and high-value products. It reduces transit damage, supports reusability, and offers long-term cost savings compared to traditional packaging materials.

How is custom XLPE foam fabricated at Foamkart?

We use advanced methods like foam splitting, CNC milling, and die cutting to shape XLPE foam into precise inserts, sheets, or cases. This ensures that every product is tailored to your exact dimensions and performance requirements.

Can XLPE foam be used for sensitive electronic components?

Yes. XLPE foam is non-conductive and can be treated with anti-static properties, making it ideal for packaging and protecting delicate electronics such as circuit boards, processors, and mobile devices.

What is the difference between open-cell and closed-cell foam for packaging?

Open-cell foam is softer and absorbs air or moisture, while closed-cell foam like XLPE is denser, water-resistant, and more durable. For packaging, XLPE foam is preferred because of its superior protective qualities.

How does Foamkart ensure the quality of its custom foam products?

Foamkart uses ISO-certified materials, state-of-the-art fabrication techniques, and stringent quality checks at every stage. Our 20+ years of experience ensures consistent quality and performance across all projects.

Is XLPE foam a cost-effective solution for packaging?

Yes. While XLPE foam may have a slightly higher upfront cost, its durability, reusability, and ability to protect products from damage make it highly cost-effective in the long run, especially for businesses managing frequent shipments.

Can Foamkart provide prototypes for custom foam designs?

Absolutely. We specialize in prototyping to help clients evaluate fit and function before committing to bulk production. Prototypes are usually delivered within 2–5 working days.

Do you offer XLPE foam services for businesses in Bangalore?

Yes. Foamkart has strong operations in Bangalore, serving industries in Electronic City, Whitefield, and Jayanagar. We also provide fast delivery across Karnataka and nearby regions.

What industries commonly use XLPE foam in India?

Industries such as automotive, electronics, aerospace, defense, healthcare, and retail rely heavily on XLPE foam for packaging and insulation. Its versatility makes it suitable for both consumer and industrial applications.

How do I start a custom XLPE foam project with Foamkart?

You can begin by scheduling a consultation with our experts. Simply share your product details, dimensions, and packaging requirements, and we’ll guide you through the design, prototyping, and production process.

Foamkart has established itself as India’s go-to expert for Custom XLPE foam and XLPE foam packaging solutions. With over two decades of experience, advanced fabrication capabilities, and nationwide delivery, we help businesses protect, package, and present their products with confidence.

Ready to upgrade your packaging or product protection? Contact our experts today and discover how Foamkart can deliver tailored XLPE foam solutions for your business.